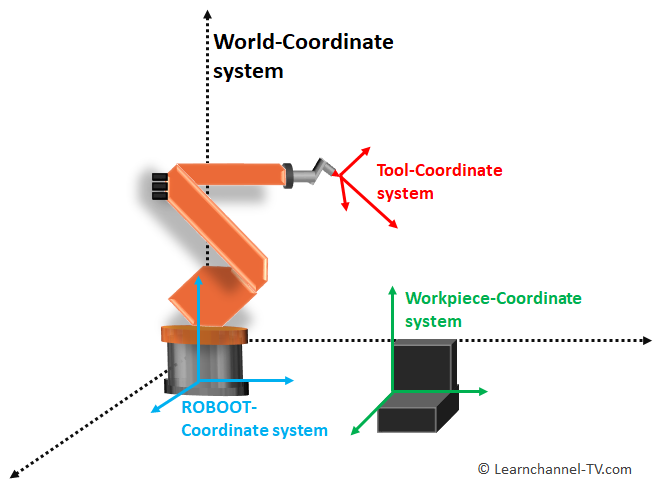

A robot uses several coordinate systems each suitable for specific types of jogging or programming. A second and more meaningful classification is done according to the working environment.

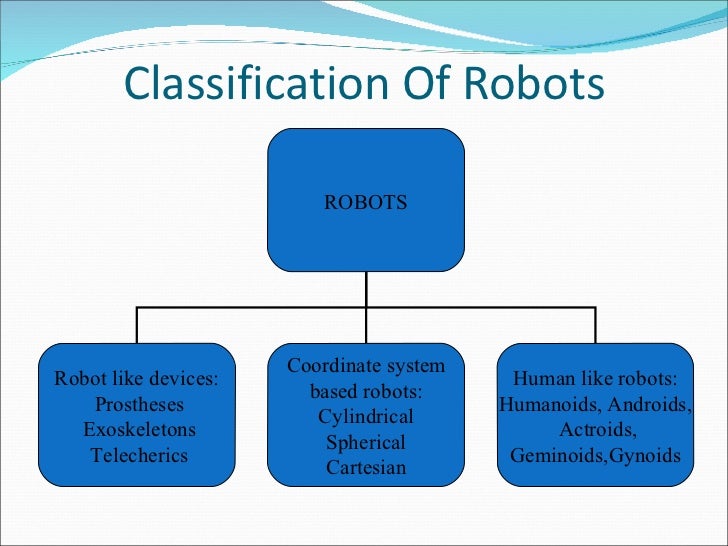

Robot Classification Working And Spesific Uitilities Of Robot

SCARA Selective Compliance Assembly Robot Arm robot is included with two parallel rotary joints to provide compliance in a plane.

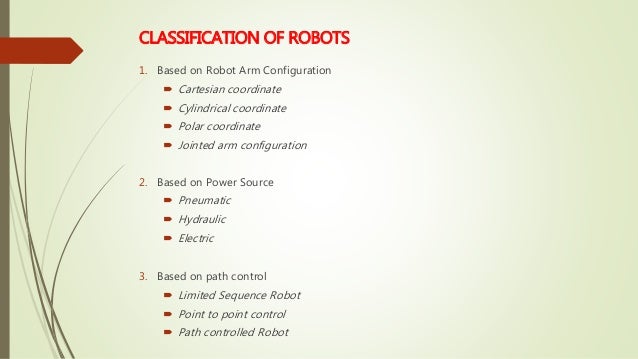

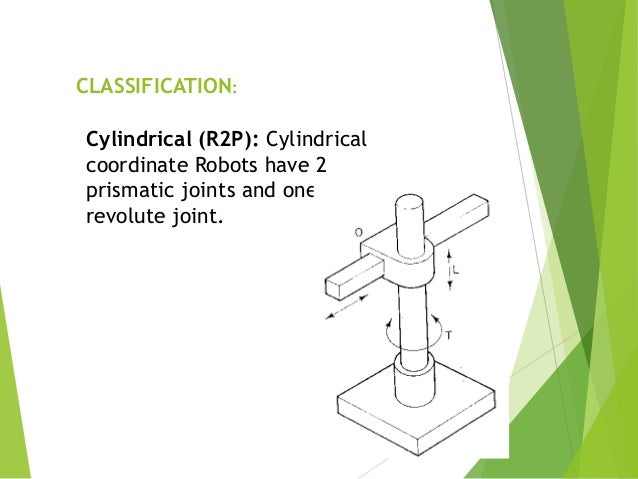

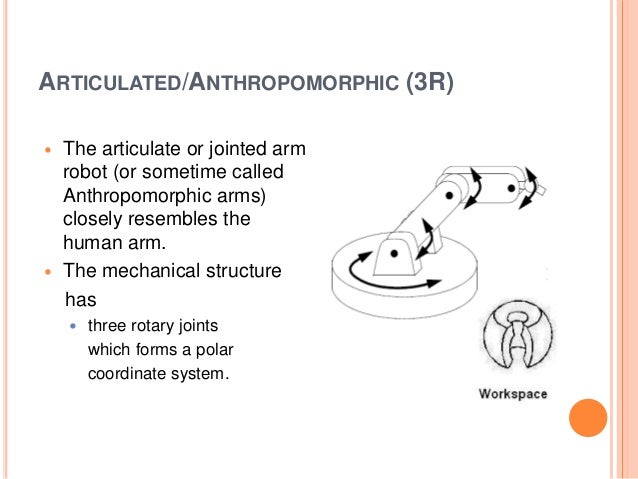

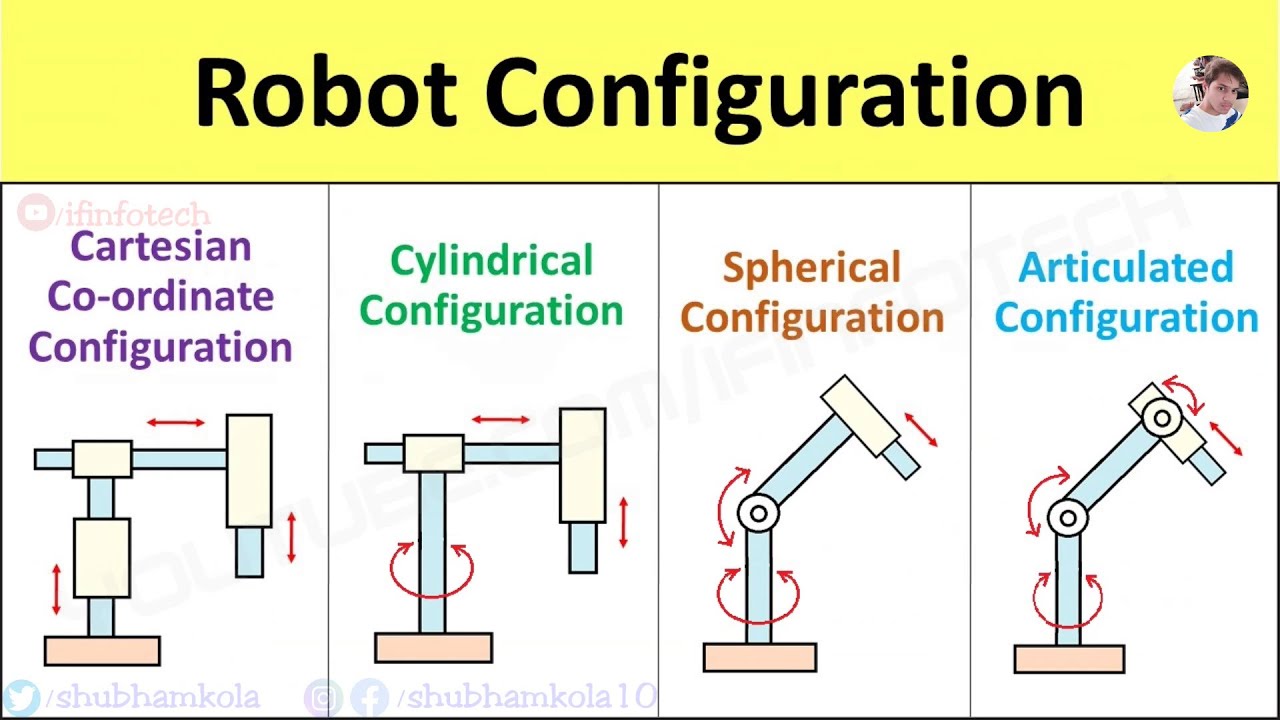

Classification of robots based on coordinate system. Requires electric drives to pump oil. A robot which has two parallel rotary joints to provide compliance in a plane Articulated robot. It is popular because it is easy to use and program.

In cases where the robots task is to move between different objects in the workplace. Robot World Coordinate System. A first distinction can be done based on the mechanical structure of robots.

Has problem of oil leakage. They can be divided into fixed robots ie. Based on reachable coordinates of a point on the end-effector.

3 according to degrees of freedom. Workpiece and or BASE coordinate system. They occupy less floor space and.

Industrial robots commonly have four or six axes. Robotic systems are generally defined as Cartesian coordinate systems. A robot whose arm has at least three rotary joints.

Good accuracy can be obtained at any point along the specified path. Hydraulic Drive It is associated with larger robots such as Unimate 2000 series. Robots are being classified on the basis of their physical configuration and control systems adopted.

When arms of a robot move in the XYZ rectangular coordinate system it is known as a Cartesian robot. Robot whose arm has three prismatic joints and whose axes are coincident with a cartesian coordinate system SCARA robot. It needs a large volume to operate and has a rigid structure.

Generally provide great speed and strength. These classifications are briefly described as follows. In controlled-path robots the control equipment can generate paths of different geometry such as straight lines circles and interpolated curves with a high degree of accuracy.

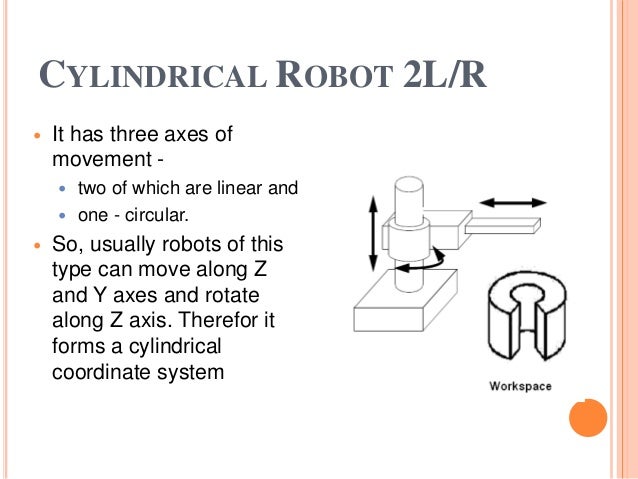

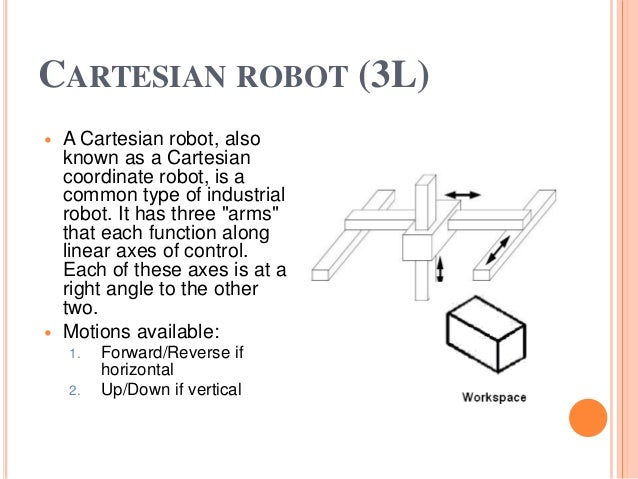

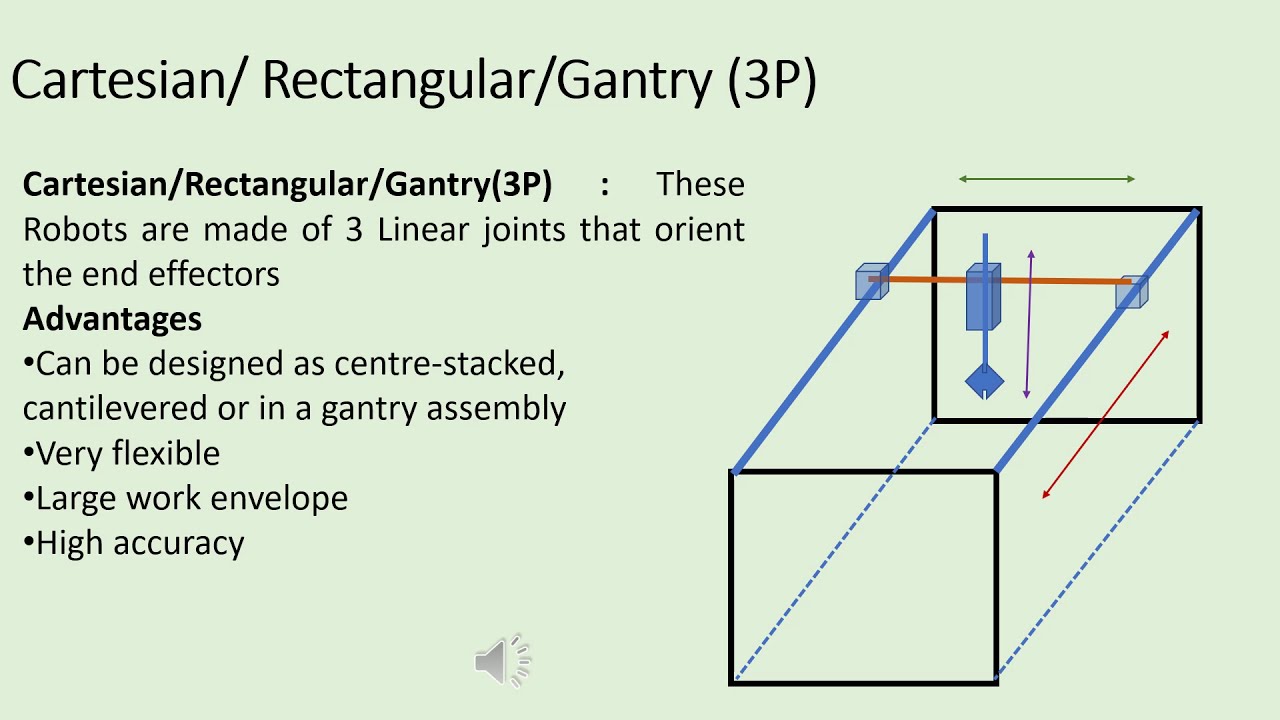

CARTESIAN ROBOT 3L A Cartesian robot also known as a Cartesian coordinate robot is a common type of industrial robot. Similarly Robots can be classified based on their coordinate systems ie. Robots with a cylindrical coordinate system have a relatively simple structure where one twisting joint T is added to two typical linear coordinates L.

Two-coordinate robots three-coordinate robots four-coordinate robots five-coordinate robots six-coordinate robots. A is designated as LLL they are also called rectilinear robots. It describes the position of the robot.

Robot targets and positions are located by measurements along the axes of coordinate systems. TYPES OF ROBOT There are five types of robots which are. Consist of links connected by linear joints L.

Cartesian - These are also called rectilinear or gantry robots. Such type of robots are used for loading-unloading operations for packing palletizing etc. The ROBOOT-Koordinatensystem is a cartesian coordinate system which has its origin at the footprint of a robot.

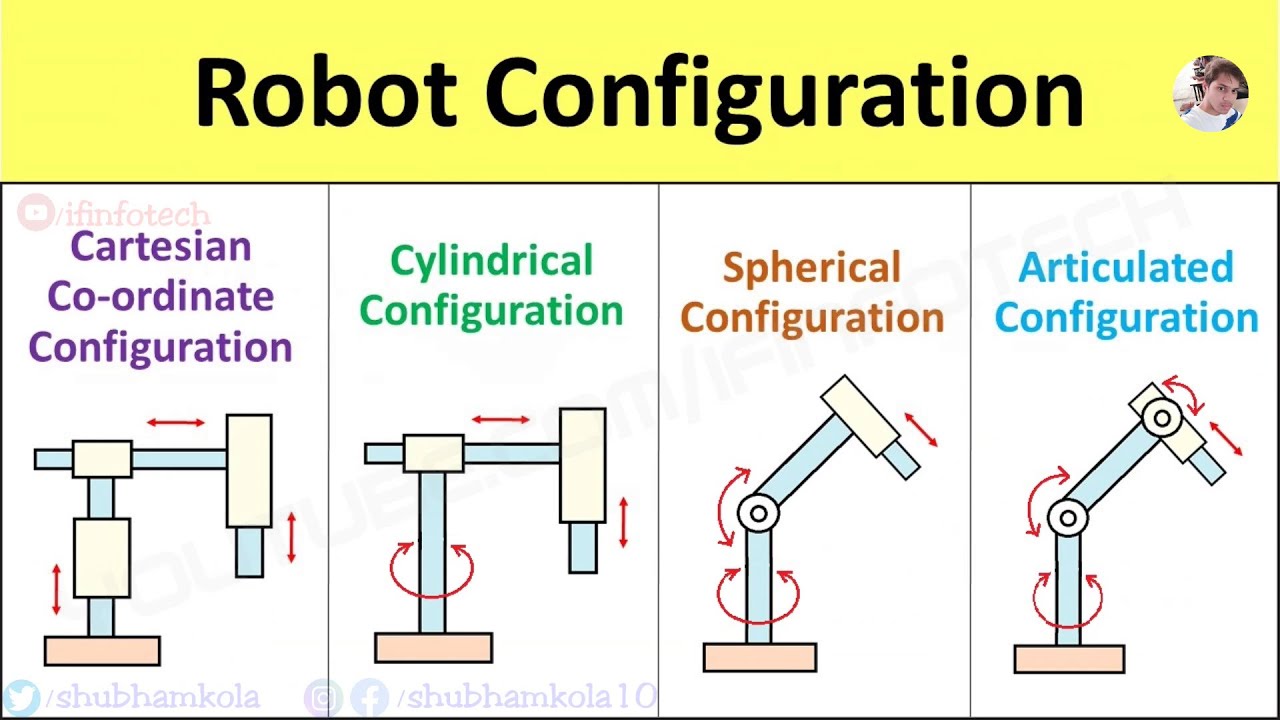

Robot Classification and Robot Reach Classification based on Physical configurations four basic configurations are identified with most of the commercially available industrial robots. They move in a straight line rather than rotate and are at right angles to each otherThe three sliding joints correspond to moving the. 1Classification on the Basis of Physical Configurations On the basis of physical configuration industrial robots are classified in four different types.

Cartesian robot consists of three prismatic joints and axes are concurrent with a Cartesian coordinate system. They also may have an attached wrist to allow for rotational movement. The Robots are mostly divided into four major configurations based on their appearances sizes etc.

Cartesian robots have three linear joints that use the Cartesian coordinate system X Y and Z. Electric Drive Electric robots are smaller and have better accuracy and repeatability. Manipulators Figure 2 and mobile robots.

Cartesian robot Cylindrical Spherical ArticulatedAnthropomorphic robot SCARA 15. Bulky and adds to floor space. Classification of robots based on the workspace geometry It is the most commonly used robot type in the industries.

Robot origin coordinate system or ROBROOT coordinate system. Furthermore mobile robots can be divided into wheeled tracked legged and undulating 3. In this robot the Kinetic structure of the arm is made up of three mutually perpendicular Prismatic joints.

Robot Tool coordinate system. A cartesian coordinate robot also called linear robot is an industrial robot whose three principal axis of control are linear ie. Can be used to actuate rotary as well as linear joints.

Introduction To Robotics Laws Classification Types Drives Geometry

Introduction To Robotics Laws Classification Types Drives Geometry

Types Of Robots Based On Configuration Plant Automation Technology

Applied Control Systems Robotics Robotic Control Robotic Syllabus

Introduction To Robotics Laws Classification Types Drives Geometry

Introduction To Robotics Laws Classification Types Drives Geometry

Robot Classifications By The Coordinate System Youtube

Types Of Robot Configuration Cartesian Coordinate Cylindrical Articulated Spherical Scara Youtube

Types Of Robots Based On Configuration Plant Automation Technology

Bem4223 Intelligent Robot Lecturer Rosli Bin Omar Phone Ppt Download