Conversely compression stress improves it. An intermediate tensile stress worsens fatigue-related performance in metals since it widens the crack.

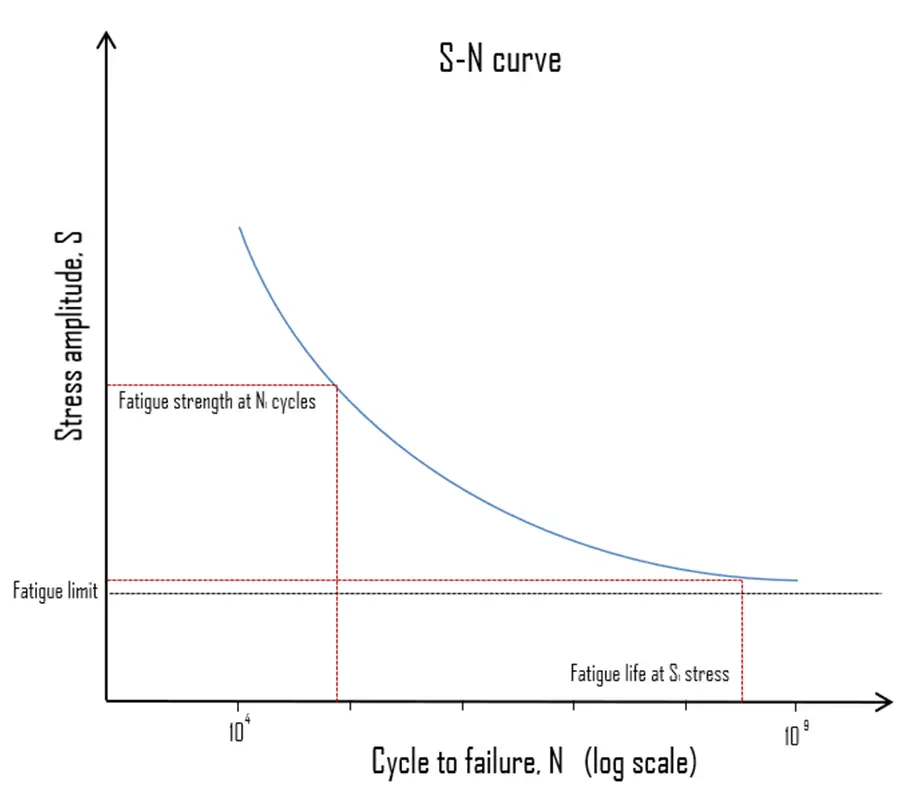

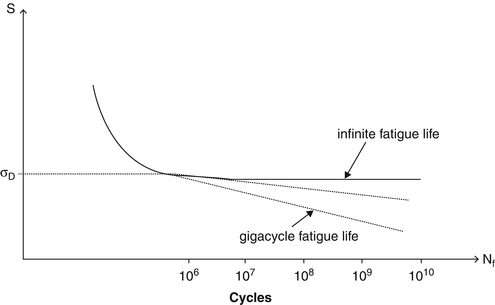

What Is Fatigue Limit Fatigue Strength Definition Material Properties

A recommended method for improving fatigue life.

How to improve the fatigue life of the metal. It differs from conventional shot peening in the way the beads or more generally the media gain their energy. Increase performance by means of residual compression stress on a thin surface layer. Crack repairs are only a temporary remedy to metal fatigue.

Metal with large grains have low yield strength and reduced fatigue limit and vice-versa. Drilling blending and patching are all ways that engineers repair crack growth on different surfaces of materials. It improves the accurancy of thickness and surface finish.

Shilko heat treatment and surface treatment can be improve fatigue life. The penning techniques introduces compressive stress. Barriers to crack growth in the form of precipitates.

École de Technologie Supérieure I agree with Serge V. In designing and manufacturing parts many factors need to be considered in order to obtain maximum fatigue life. Cold Rolling is the process that compresses and squeezes sheet metal between rollers.

Aims to improve the fatigue life of metal components. During the manufacturing process micro. It is a cold working process which impacts the surface with a tool or small metal balls creating plastic deforms.

It consists in bombarding the surface of the component with a stream of small high hardness spheres called shots. Avoid sudden change in cross section. These components come in many forms including stampings wire forms laser-cut tubes and even machined parts.

To improve the fatig ue strength of the material one of the most used method is surface treatment of the mate rials in which hardness wear resistance an d. Metal prosthetic devices to promote mechanical interlock and even to invoke surface chemistry to stimulate bone growth through an increase in osteoconductivity 2. Introduction Shot peening is a widely used mechanical surface treatment in the automotive and aerospace industries to improve the fatigue life of metallic components.

Application of a composite retrofit to a fatigue-vulnerable connection detail effectively reduces the stress range that the steel substrate experiences because a new load path is provided through the composite retrofit. Broadly these are processes that affect either a thin. However at higher temper atures the coarse grained metal is seen to show better fatigue properties.

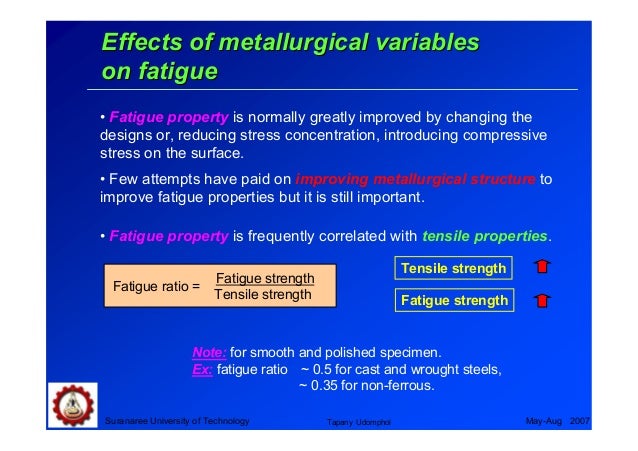

Figure 1 Comparison of steel and aluminum fatigue behavior One of the methods to improve the fatigue life of the materials is surface treatments sometimes referred to as post-processing. 124 Factors influencing fatigue life Fig. Electropolishing has become a common metal finishing process used to help improve the life of metal parts that flex cycle twist and bend.

Carburizing and nitriding produce higher strength and hardness at the surface and thus improves fatigue life. Our process uses the vibration of the top surface of a sonotrode to impulse the beads to the part area to be treated. Three of the most common methodscoatings used for metal implants include sintering of metal beads diffusion bonding of a wire mesh and deposition of metallic plasma sprays.

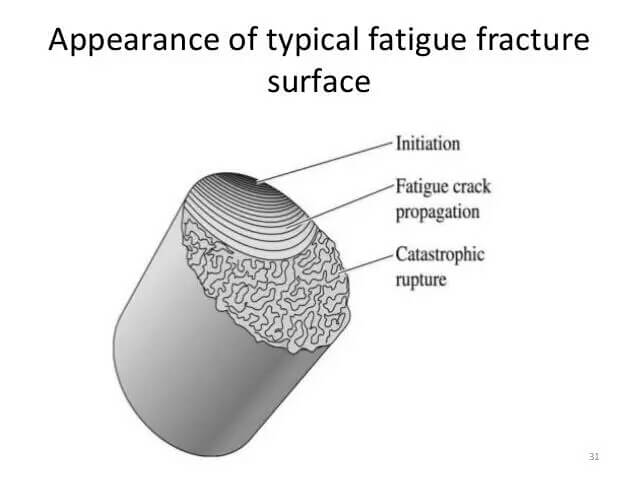

Fatigue phenomena occur when a material is subjected to fluctuating stresses and strains which lead to failure due to damage accumulation. Remove metal so there is a smooth transition between sections. Different methods including the Palmgren-Miner linear damage rule- LDR- based multiaxial and variable.

Improve Fatigue Life of Metal Parts. By scanning and transmission electron-diffraction microscopy the structure and phase states and defect substructure of these materials may be investigated. Avoid sharp corners use Temple radius to reduce stress concentration level.

The increase in the fatigue life of the steel is due to the transformation of the surface structure of the material under the action of the intense pulsed electron beam. Metallic materials are extensively used in engineering structures and fatigue failure is one of the most common failure modes of metal structures. The overall effect is that the probability of crack nucleation and fatigue failure is reduced.

Repairing small cracks can help slow down crack growth and prevent catastrophic failure. They play a very important role in the appearance function and life of the product. One way to improve the fatigue strength is to introduce compressive residual stress which gives better results.

Types of fatigue cycles A.

Fatigue Strength Improvement Methods Sciencedirect

Fatigue Strength Improvement Methods Sciencedirect

How To Improve Metal Fatigue Strength Lsp Technologies

Solved How Can You Improve Fatigue Life Of A Steel Except Chegg Com

How To Improve Metal Fatigue Strength Lsp Technologies

Professional Engineers Tell You How To Improve Fatigue Life Of Metal Components To Avoid Equipment Accidents Yaang

Improving Fatigue Life Of Metal Am Parts Additiva

How To Improve Metal Fatigue Strength Lsp Technologies

Fatigue Of Metals Part Three Total Materia Article

Metal Fatigue Curtiss Wright Surface Technologies

Pdf A Study On Improvement Of Fatigue Life Of Materials By Surface Coatings

Professional Engineers Tell You How To Improve Fatigue Life Of Metal Components To Avoid Equipment Accidents Yaang