Normal beer fermentations all yeast reaches a state of starvation and in this condition rapidly autolyse and the autolysates impart undesirable flavours to the finished beer. This is a dark aromatic and full-bodied beer with a slightly sweet taste because it is only slightly hopped.

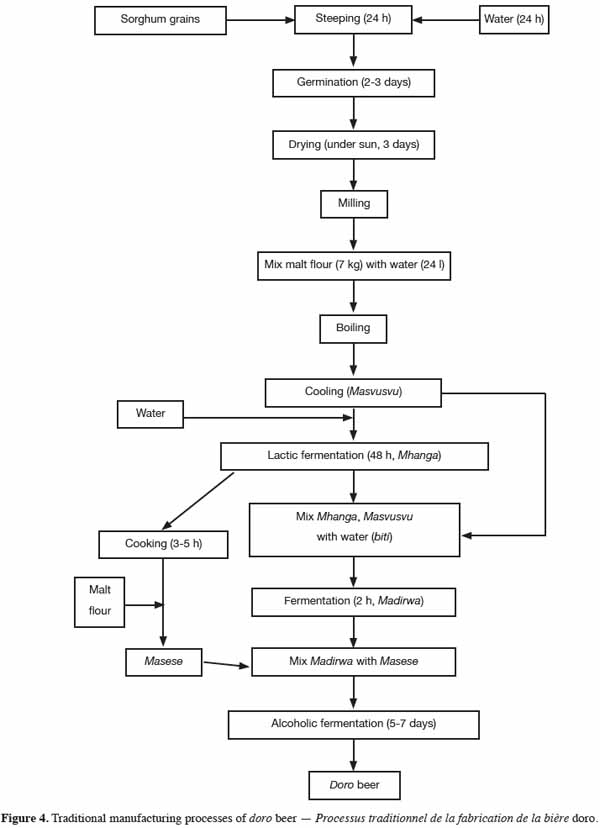

Characteristics Of African Traditional Beers Brewed With Sorghum Malt A Review Universite De Liege

Top-fermenting Saccharomyces cerevisiae is used for beer manufacturing.

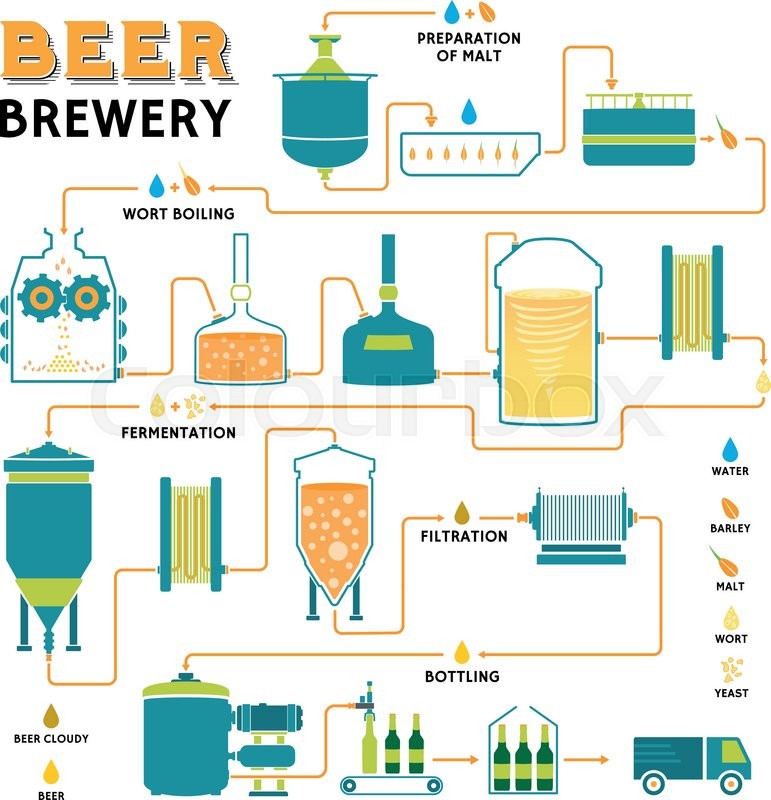

Manufacture of beer process. This drink doesnt have a pleasant taste because it contains butane-23-dione and pentane-23-dione. Main ingredients of most beers are. Basically beer is produced from all grains but at the industry level produced only from barley.

The fact that these products have a slightly bitter taste makes them the perfect raw material for beer. The dried barley. Types of barley beer.

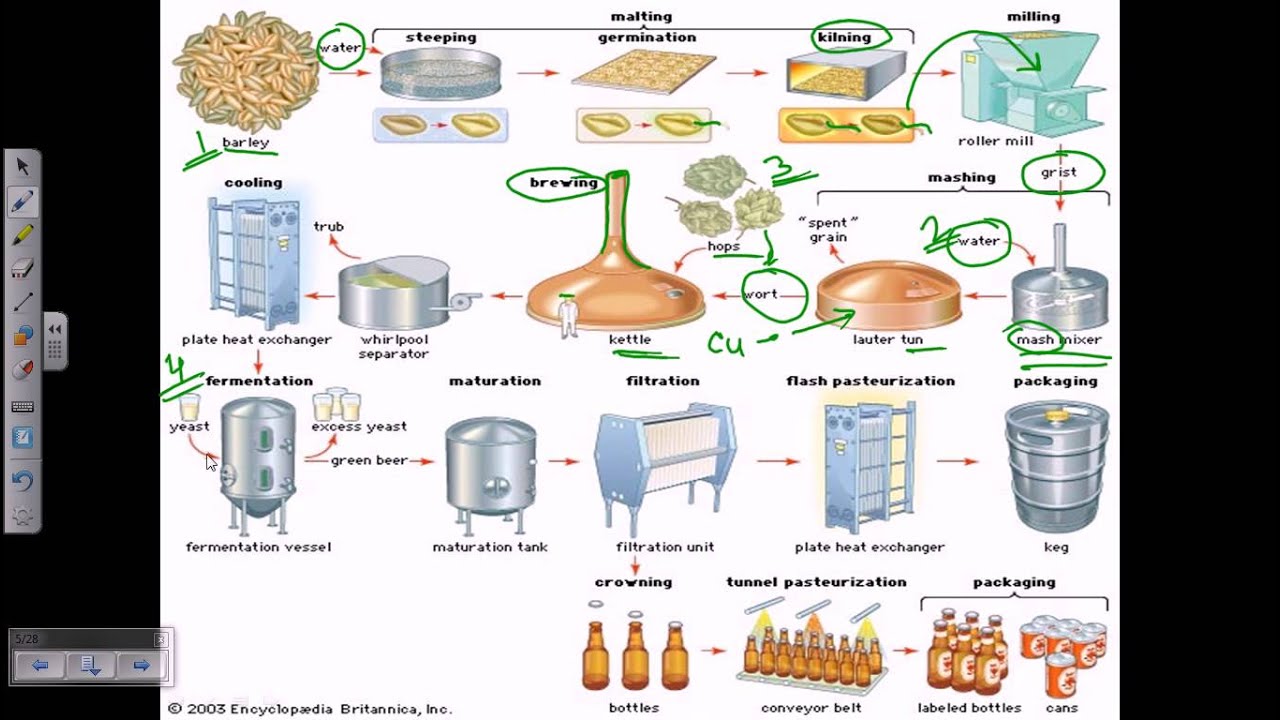

Barley is the commonly used cereal for. Steeping Germination and Kilning. Typically beer is made from malted barley and flavored hops.

FMost Beer is also flavored with hops which add bitterness and act as natural preservatives though other flavorings such as herbs or fruits may occasionally be included. The brewing water is high in carbonates but low in other ions. BottlingThe final stage of the beer productionprocess is transferring the beer intodifferent kinds of containersbottles barrels cans etcBefore or after bottling the beer needs tobe biologically stabilised.

The alcohol content could be quite high varying from 2 to 5 per cent alcohol. Beer is produced from barley grains. The germinated seed are then killed by slow heating at 80 This process is called kilning.

Dont worry since their level decreases as the beer ages. Types Of Yeasts Used For Beer Making Ale yeast They can ferment at a higher temperature and form more esters. Malting is the process of preparing barley for brewing.

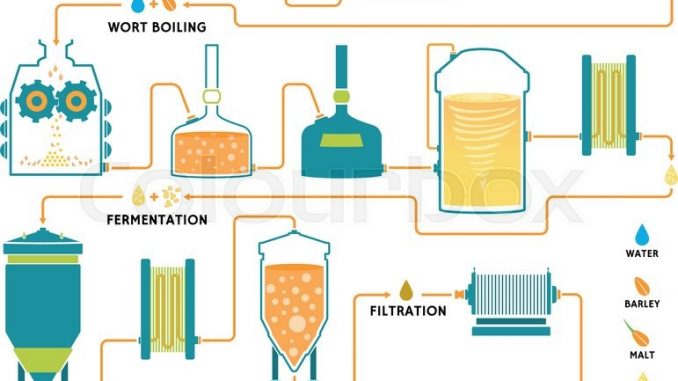

This beer goes to cellars for a maturation process that lasts from a few weeks to a couple of months. Beer making Process October 15 2020 Sushmita Dura Food Science Protocols and Techniques 0 Brewing is a beer production process which can be obtained by using basic ingredients like water malted barley hops and brewing yeast for the fermentation. Yeast metabolizes the sugars extracted from grains which produces alcohol and carbon dioxide and thereby turns wort into beer.

Commonly barley and other starch suppliers have to be malted to facilitate starch dissolution. This takes place during. However the yeast concentration can be up to 100 grams of yeast with a moisture content of 80 in each litre of beer fermenting.

The resulting product is a dried cereal grain called Malt. Word brewing is derived from Bieber its means to drink. This operationmay be carried out cold sterilisingfiltration or hot usingpasteurisation which may be done either 28.

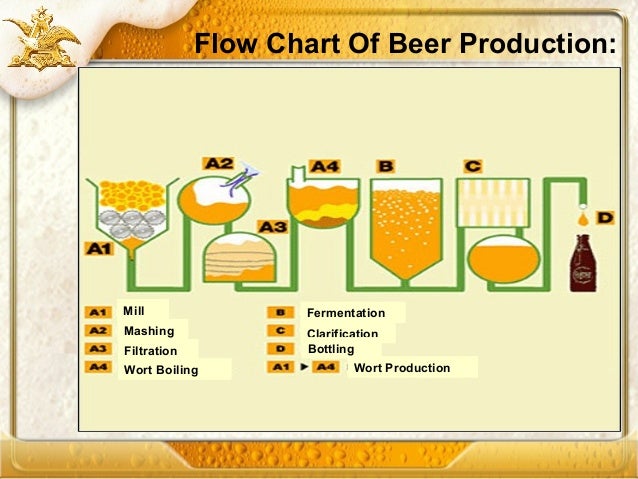

Beer production process 1. Once completed the beer is ready to be packaged and thats a whole other fascinating process explained in the video. This is the first and basic step of beer brewing.

Though technically equipment sanitization does not form a part of beer brewing it is a crucial. The final product of fermentation is the so-called young or green beer. The germinating process is then interrupted at the optimal stage by the drying kilning.

The first step in the production of beer is malting. Water barley hops yeast. While production processes may vary depending on the type of beer youre producing the basic process for making beer remains the same.

In this phase the enzymes amylase are formed which are needed for the starch separation. Weiss beer of Germany is made from wheat and steam beer of California. After reaching its full potential the beer is filtered carbonated and transferred to the bright beer tank where it goes through a cellaring process that takes 3-4 weeks to complete.

The Beer Brewing Process Explained Equipment Sanitization. Beer is an alcoholic drink that is manufactured by brewing and fermenting of cereals. The process of beer production is known as brewing.

Manufacturing beer is a complex mixture of technical and bio-technological processes. The malting process is comprised of three steps with each step unlocking the starch within the barley. Barley grains are first cleaned and then soaked in water for about 2.

Maize barley and rice can also be used as a. Steeping wetting grains activation of enzymes germination. Firstly the fresh barley gets soaked in water and put in the so-called germinating boxes to germinate.

Beer Processing Steps The process of beer making involves several steps and a series of chemical reactions in order to produce a quality product. Malting is the process of germinating a seed so that it can be used effectively in a brewery to make sweet sugary liquid called Wort.

Beer Brewing Process Brewery Factory Production Vector Image

Beer Production Overview Youtube

Brewing Beer Production Process Online Biology Notes

Brewing And Distilling Process Ibd Asia Pacific

Beer Brewing Process Brewery Factory Production Stock Vector Illustration Of Ingredients Brewing 113553679

Beer Production Food Microbiology The Biology Notes

The Brewing Process Aslan Brewing Co

Brewing Beer Production Process Online Biology Notes

Beer Definition History Types Brewing Process Facts Britannica

A Schematic Of The Brewing Process For The Production Of Irish Red Ale Download Scientific Diagram