Evaluation of Tensile Properties of Textile Materials-2 contd Evaluation of Tensile Properties of Textile Materials-3 contd Evaluation of Tensile Properties of Textile Materials-4 contd Evaluation of Tensile Properties of Textile Materials-5contd Module 8. Significance of Bending and Twisting.

Tensile Properties Of Textile Fibers Textile Study Center

The mechanical behavior of textile fibers fiber structure is influenced by the amount of moisture in the specimen.

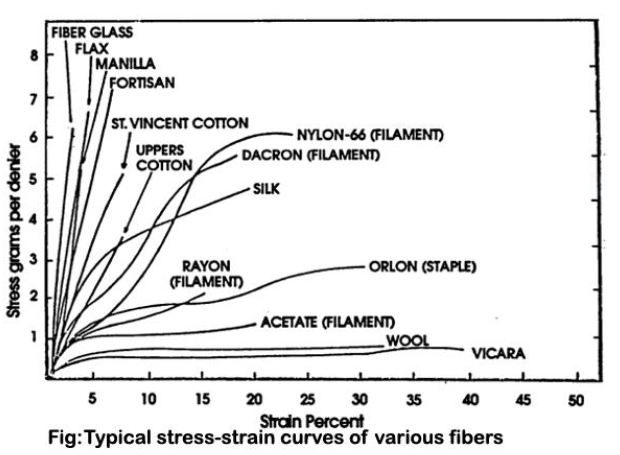

Tensile properties of textile materials. It is fundamental for architectural fabrics that function primarily in tension. From these measurements the following properties can also be. Also the tensile behaviour of the fibres is linked to their microstructure.

Chemical treatment may also affect the tensile properties of the specimen. ISO 13934 consists of the following parts under the general title Textiles Tensile properties of fabrics. The mechanical properties of a specimen before and after straining changes mentionable.

The properties that describe a fiber strength elongation elasticity abrasion resistance modulus of elasticity etc. A rope or wire under load is subject to tensile forces. Mechanical Properties of Textile Fibers.

The strength of any material is derived from the load it supports at the break and is thus a measure of its limiting load-bearing capacity. The moisture relationships of the various fibers type differ. Flexural Properties Tensile properties of textile fibers Tensile properties indicates how a material fiber will react to the forces being applied in.

It is found that duration of retting has no effect on the tensile properties of hemp fibres. Properties of Fabrics for Tensile Structures the different properties of a fabric which are considered for design are 1. Tensile - Pertaining to forces on a body that tend to stretch or elongate the body.

Certain mechanical properties of textiles using mainly tensile testing machines eg. To mean this International Standard. Tensile Strength It is a basic indicator of relative strength.

Therefore its a vital property when yarn manufacturing and processing. Flexural Properties of Textile Materials The behavior which shows by textile material during bending is called flexural bending property. The bending and twisting of fibers influence the behavior of bulked yarn and the drape and handle of fabrics.

A range of international test standards are being used to ensure the highest quality of product. Twisting and bending both play a part. Frictional properties are because of the friction between the fibers.

Mechanical properties of fibers. Evaluation of Textile Materials. The effect of processing conditions such as retting duration mercerization in sodium hydroxide and hydrothermal treatment on the tensile properties of these fibres is reported.

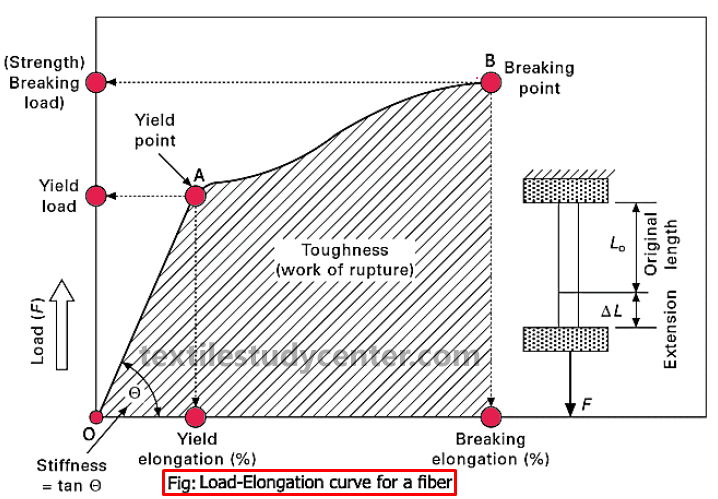

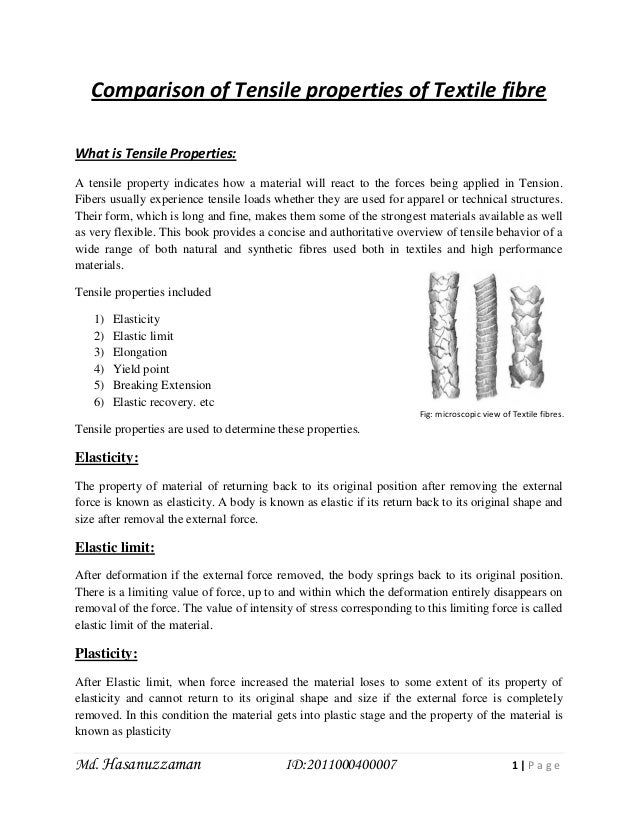

Tensile properties included 1 Elasticity 2 Elastic limit 3 Elongation 4 Yield point 5 Breaking Extension 6 Elastic recovery. Properties that are directly measured via a tensile test are ultimate tensile strength breaking strength maximum elongation and reduction in area. 12 Zeilen Tensile properties are composed of the reaction of the materials to resist when forces are.

Tensile properties seam tensile properties tear properties and seam slippage. Etc Tensile properties are used to determine these properties. These properties are shown during processing.

The results obtained by one of the methods should not be compared with those obtained by the other methods. Too high friction and too low friction isnt good for yarn. Handbook of Properties of Textile and Technical Fibres Second Edition introduces tensile properties and failure and testing of fibers also examining tensile properties and the failure of natural fibers such as cotton hemp flax agave wool and silk.

Tensile testing also known as tension testing is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. The property of material of returning back to its original position after removing the external force is known as elasticity. The importance of Flexural properties is required when we wear cloth.

The procedure for these standards agrees where appropriate. Next the book discusses the tensile properties and failure of synthetic fibers ranging from polyamide polyester polyethylene and carbon fibers. Determination of maximum force and elongation at maximum force using the strip method.

Mechanical Properties of Textile Fibers. Evaluation of Yarn Fabric Hairiness. Amphibio wanted to quantify the strength and mechanical properties of various single fibres multifilament yarns woven and knitted textiles and fabrics.

Standard Test Method for Tensile Properties of Single Textile Fibers.

Handbook Of Tensile Properties Of Textile And Technical Fibres Sciencedirect

A Tensile Strength And B Tear Strength Of Woven Fabrics Download Scientific Diagram

Definitions Of Some Basic Terms Textile Fibre Properties Online Textile Academy

Structure And Properties Of Textile Materials Sciencedirect

Tensile Properties Of Textile Fibers Textile Study Center

Iso 13934 1 1999 Textiles Tensile Properties Of Fabrics Part 1 Determination Of Maximum Force And Elongation At Maximum Force Using The Strip Method Iso Tc 38 Sc 24 Amazon Com Books

Tensile Properties Of Yarns 3 2 Mechanical Properties Of Fabrics Download Scientific Diagram

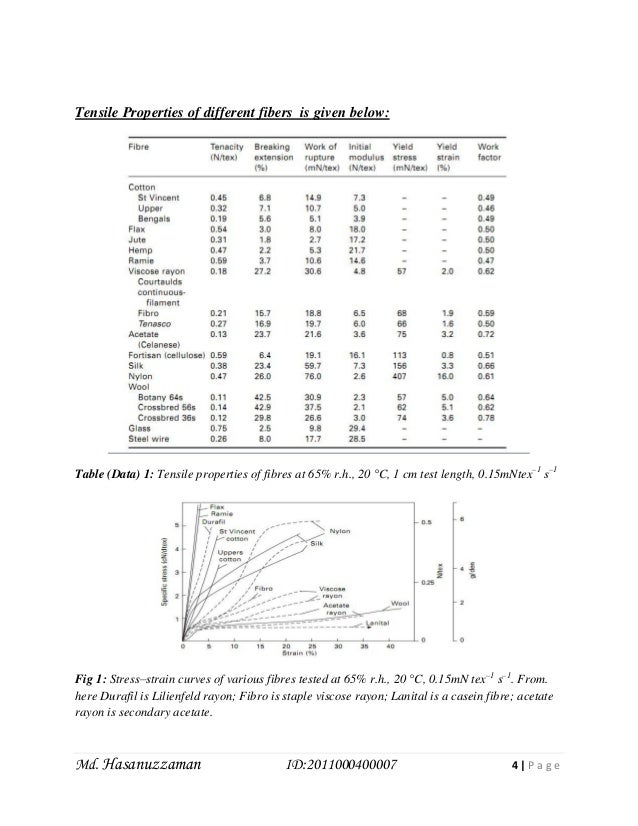

Comparison Of Tensile Properties Of Textile Fibre

Mechanical Properties Of Textiles

Pdf Mechanical Properties Of Textile Fibers Mechanical Properties Of Textile Materials Textile Learner Sohanur Rahman Sabuj Academia Edu

Comparison Of Tensile Properties Of Textile Fibre

Tensile Properties Of Yarns 3 2 Mechanical Properties Of Fabrics Download Scientific Diagram

Tensile Properties Of Textile Fiber And Textile Material

Tensile Properties Of Textile Yarn Elasticity Physics Deformation Engineering